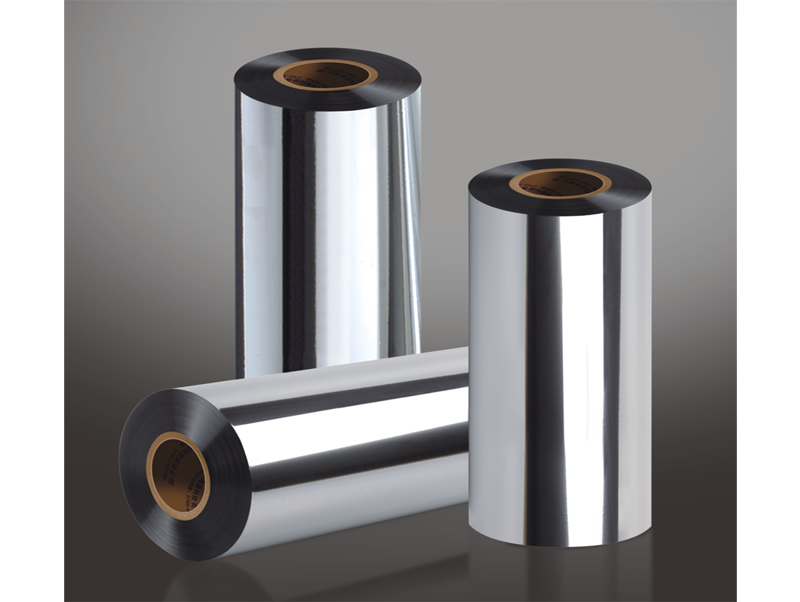

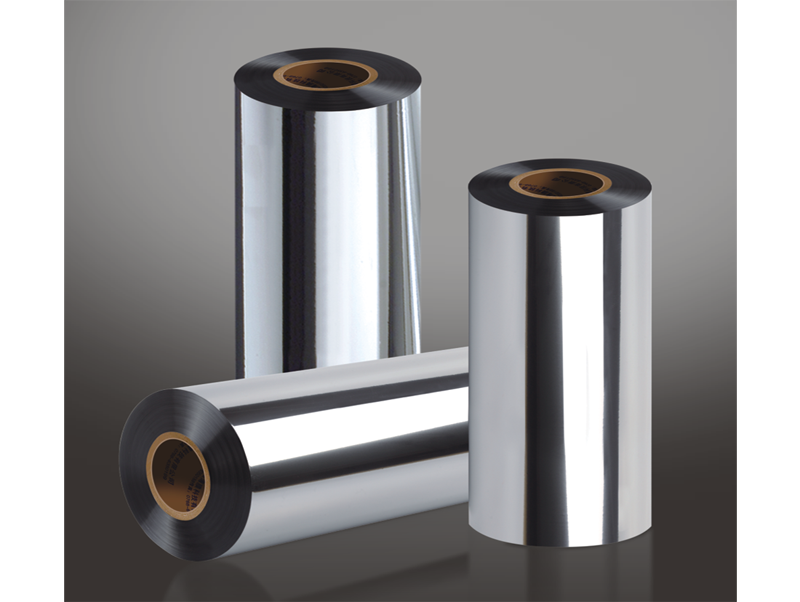

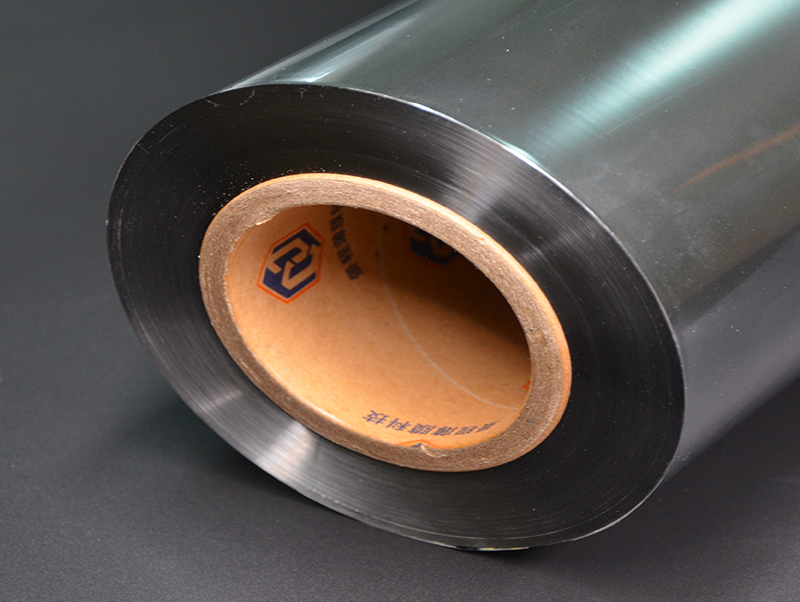

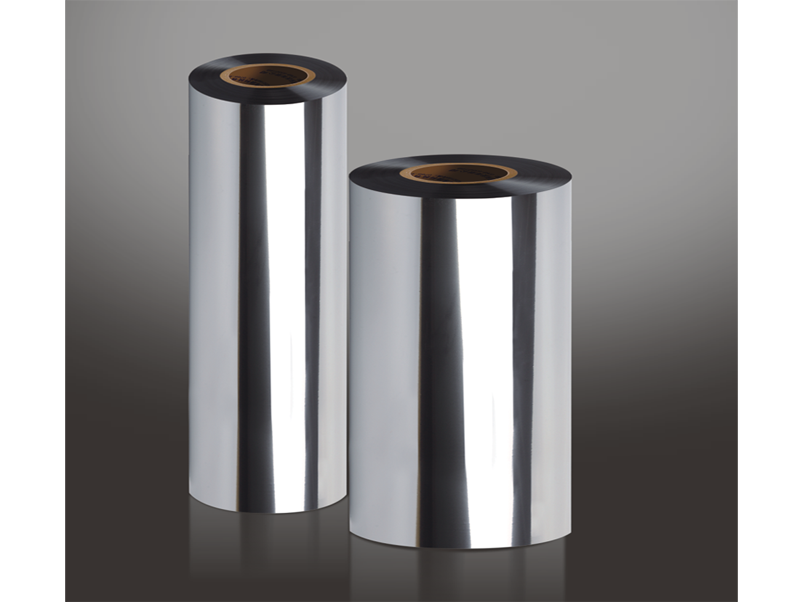

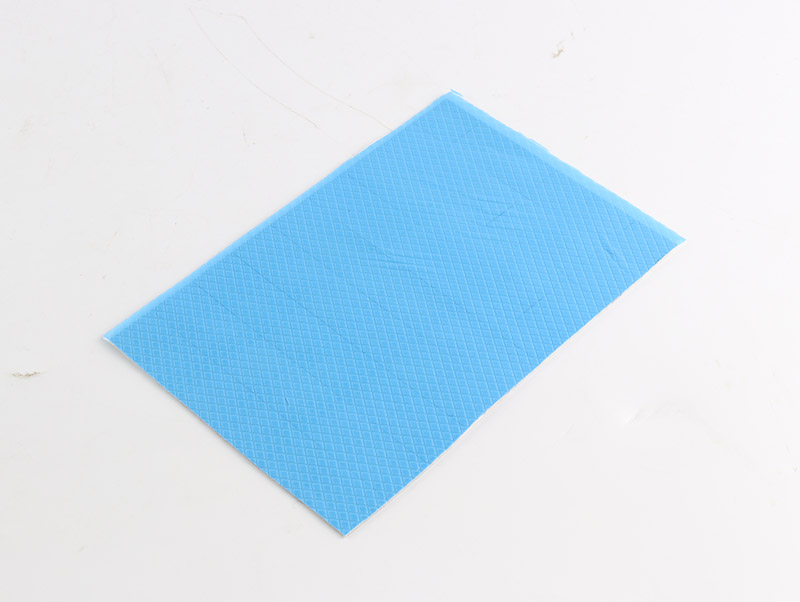

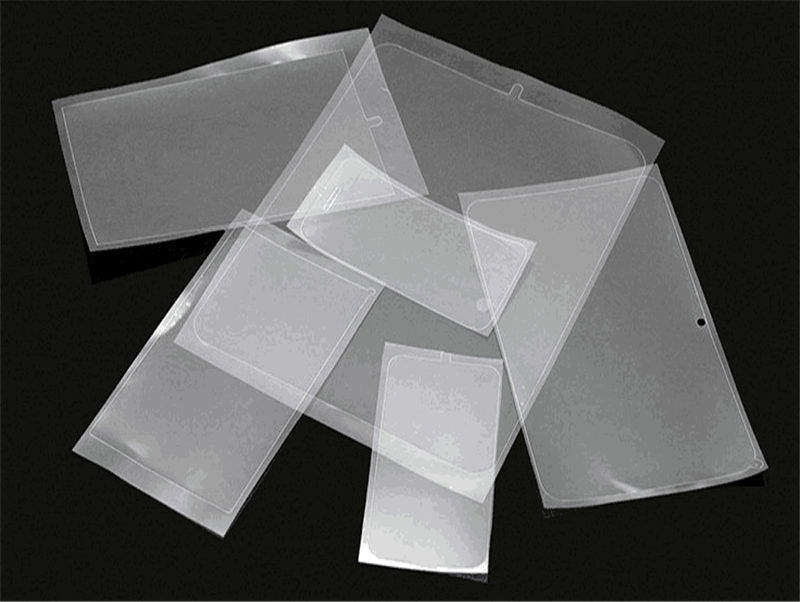

The VMCPP film is made of the CPP aluminium metalizing substrate film metalized in vacuum metalizing machine. It is usually divided into low temperature VMCPP, ultra-low temperature gas-filled VMCPP, high bonding strength VMCPP, low friction VMCPP corresponding to different functional applications. As heat sealing inner layer, VMCPP film is laminated with BOPP, BOPA, BOPET and other materials for bag making. It is suitable for various kinds of food, medicine and cosmetics packaging.

Characteristic:

*Good barrier performance

*Excellent light-shading performance

*Excellent glossy appearance of aluminium metalizing layer,excellent foil ability to ink colour.

*Good laminating adaptability

*Excellent heat sealing strength